Him Darji

Him DarjiRole of MEP Shop Drawings for Successful Building Construction

Him Darji

Him Darji

Send Us Your Requirement

The architecture and construction field is complex and amalgamations of multiple processes for desirable results. The industry is now surrounded by the latest technology and innovations that ease the complex process of construction operations. In an ever-growing economy, technology has always paved its way into industries, especially the AEC industry, which has altered the reality of the industry. Building information modeling was one of the groundbreaking technologies that hit the architecture and construction industry. However, it is a broader concept that brings a lot of other services for construction operations. With that, MEP services are critical role players in building functionality. Integrated with BIM technology, MEP BIM services allow architects and engineers to successfully plan and install complex systems in the design model.

MEP is referred to as mechanical, electrical, and plumbing, which are the three disciplines of the building and serve as a functional system as well. However, installing all three disciplines is a complex job, where MEP BIM services come into play. It ensures all three systems’ smooth, seamless, harmonized installation without clashes or errors. MEP systems provide efficient heating, ventilation, air conditioning, electrical, and plumbing functions to the building. These systems ensure that the infrastructure is fully functional and has a livable environment.

Hence, the importance of MEP systems is highlighted here as the heart of any construction project, which requires sheer attention, accuracy, and efficiency during the design and installation phases. AEC professionals ensure that these three systems do not collide or clash and are at full potential of functionality without any risk to the building or the occupants. Therefore, to make a successful design and installation process, these systems require accurate and reliable MEP shop drawings or a blueprint before MEP systems are installed.

Install MEP Systems with Accurate MEP Shop Drawings

Talk to Us

Understanding the sheer importance of MEP systems in the construction process is correlated to MEP shop drawing services, which again serve as vital operations in the pre-construction phase. With the help of the shop drawings, MEP professionals can easily design and install the three systems without any interference. For a better and deeper understanding, let’s explore MEP shop drawings and how they are a significant key to the success of construction projects.

Understanding MEP Shop Drawings in Detail

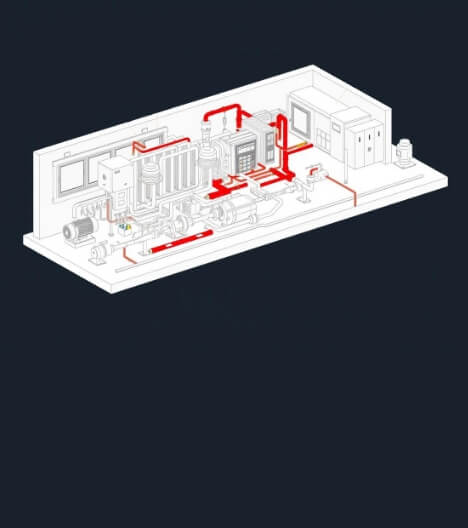

As discussed, the importance of MEP BIM services in the construction process is evident, and all three disciplines will be installed in harmony in the model. As a matter of fact, to install these systems with utmost accuracy, professionals require drawing that depicts the proper installation. With the help of MEP shop drawings, it can be achieved, and the process can result in the best outcomes; hence, it makes a significant step in the construction process. Without the proper detailing or drawings, MEP system installation can result in chaos, errors, and clashes between the mechanical, electrical, and plumbing systems. MEP shop drawing services are the process of making detailed technical drawing illustrations that offer insights into how three systems will be installed and function in the project.

In simple terms, MEP shop drawing services are the cornerstone of successful installation and facilitate accuracy to maintain the harmony between MEP systems. Typically, these drawings are created by the MEP engineers and further used by AEC professionals to coordinate the design, site execution, and assembly of mechanical, electrical, plumbing, and fire protection systems. As a matter of fact, these technical drawing illustrations entail detailed information about the materials, equipment, and process for installation in the model and on the construction ground.

Furthermore, detailed shop drawings are a novel way to ensure the project is constructed on the agreed specifications. This facilitates clear communication, quick collaboration, and informed decision-making among the various stakeholders. MEP engineers usually create detailed drawings using CAD software that allows architects, engineers, and other professionals to maintain the harmony and synchronization between the three disciplines of the infrastructure. Other than that, the MEP BIM service benefits HVAC contractors in various ways, so MEP technical drawings are curated. As an advantageous process as it is, MEP shop drawing services have a fair share of challenges that may occur during the vital process; some of the challenges are;

- Lack of communication among different professionals

- Lack of knowledge of BIM software or management

- Lack of coordination

These challenges may or may not occur during the process; however, it is still significant to overwatch the procedure to reduce costly overruns and time delays in the construction project. Other than that, using shop drawing services can vitally offer a range of advantages to the project, such as;

MEP Shop Drawing Advantages

Better clarity, accuracy, and efficiency

Enhanced project management

Synchronized MEP systems

Reduced Rework

Minimized scope of errors/clashes/conflicts

Reduced cost overruns and project delays

Enhanced material and equipment planning

Improves communication and collaboration in the pre-construction stage

Since MEP shop drawings services play a key role in determining the overall success of the construction project, they usually support fabrication, installation, assembly, and the overall maintenance of MEP systems in the infrastructure. As these are detailed and technical informative drawings, MEP drawings are curated separately to enhance their accuracy and further used by BIM modelers to integrate with BIM services.

Types of MEP Shop Drawings Services

Shop drawings are detailed technical drawings that depict the location, material, and MEP coordination between the systems. Although these sets of drawings are illustrated separately and further synchronized in the BIM model, the following are the types of MEP shop drawings that are vital for architects, engineers, and contractors.

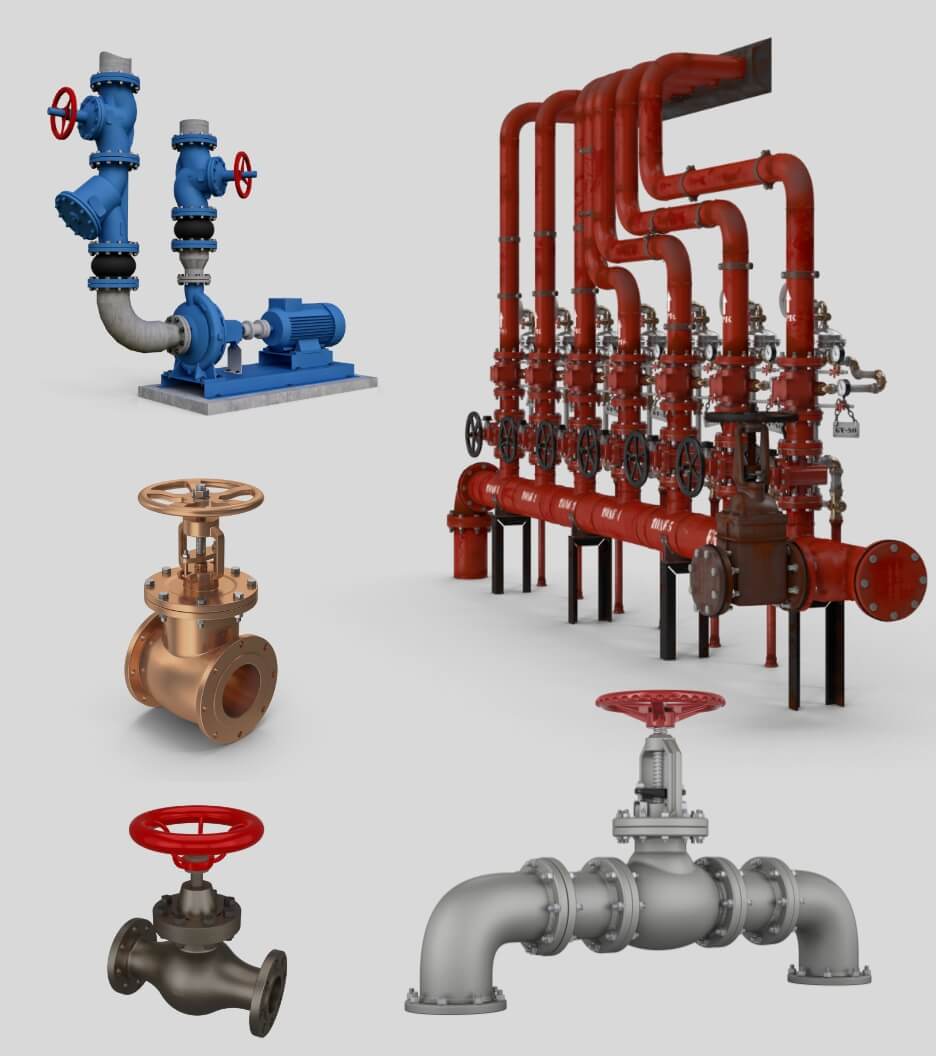

- Mechanical Shop Drawings: Mechanical shop drawings include intricate details of design and the operations of mechanical systems. These drawings help coherently demonstrate the effectiveness of HVAC systems in the infrastructure to enable proper temperature, air ventilation, and conditioning functionalities. Moreover, they are further utilized in mechanical drafting services and assist professionals with material and equipment parts.

- Electrical Shop Drawings: Another segment of the MEP system is the electrical, which is responsible for power supply functions in the infrastructure. Electrical detailed drawings are highly technical and outline the layout of electrical equipment in the building. This helps offer a detailed map for electricians to install and ensure seamless power supply.

- Plumbing Shop Drawings: Plumbing is the third segment of the MEP BIM service process, which is entitled to the effective installation of plumbing equipment, sufficient water supply, and drainage system. Plumbing shop drawings are crucial in properly installing pipes, fixtures, and other equipment supporting plumbing procedures.

These are the three main types of MEP shop drawings. MEP engineers need to curate detailed and accurate illustrations, as these are further referred to in the MEP BIM services process, and integrate precise installation of mechanical, electrical, and plumbing systems without any conflicts or errors.

Concluding Remarks

MEP shop drawings are not just detailed illustrations but a key player in determining the success of building construction. Once the construction work is completed, MEP drawings offer accurate drawings for repairs and fixating any cause. As a result, this enhances the lifecycle of the building with efficiency and accuracy. UniquesCADD offers MEP shop drawing services by a team of professionals and the use of the latest technology.